MASS LOADED VINYL BARRIER SERVICES IN DUBAI

Struggling with excessive noise that disrupts your peace? Waseem Technical Services offers a solution: Mass Loaded Vinyl (MLV) Barriers. These innovative soundproofing barriers significantly reduce noise transmission, fostering increased productivity, improved communication, and a more peaceful environment.

What are MLV Barriers?

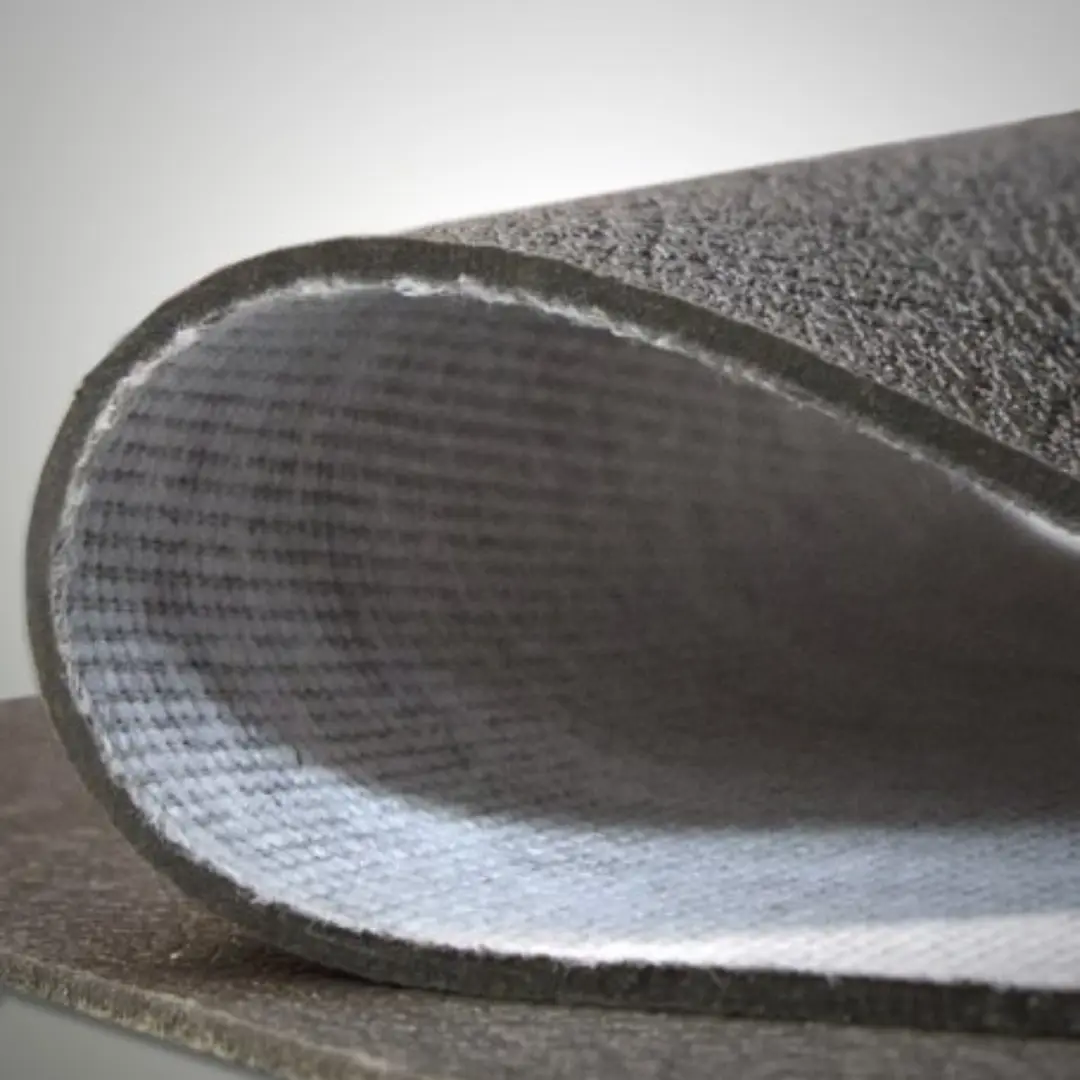

MLV Barriers are soundproofing panels comprised of a limp, heavy material – typically polyvinyl chloride (PVC) – sandwiched between facings like sheet metal or fabric. This unique composition effectively dampens sound waves, preventing them from traveling through the barrier.

Key Advantages of MLV Barrier:

Soundproofing:

MLV acts as a formidable barrier against a vast spectrum of sound frequencies. Whether it’s boisterous conversations, thumping music, or the incessant hum of traffic, MLV effectively dampens these airborne disturbances, creating a haven of serenity within your space.

Flexibility:

MLV’s adaptability is a game-changer. Unlike rigid materials, MLV conforms effortlessly, allowing for easy customization to perfectly fit the contours of your walls, ceilings, floors, or even around pipes and ducts. No awkward gaps or compromised soundproofing here!

Safety First:

MLV prioritizes your well-being. Comprised primarily of non-toxic materials, it eliminates concerns about exposure to harmful chemicals like lead, asbestos, or formaldehyde. Rest assured, MLV creates a quieter environment without compromising indoor air quality.

Built to Last:

Durability is another feather in MLV’s cap. This robust material stands strong against environmental fluctuations, including moisture and temperature variations. Over time, MLV maintains its integrity, ensuring lasting performance and a continued shield against noise intrusion.

Cost-Effective:

Considering its exceptional effectiveness and enduring qualities, MLV emerges as a cost-effective path towards achieving superior sound control. The significant reduction in noise levels and the creation of a peaceful environment translate to a wise investment in your overall well-being.

Space Savvy:

Deceptively thin (often around 1/8 inch or 1/4 inch), MLV packs a powerful punch in sound isolation. This translates to significant noise reduction without stealing precious square footage from your living area.

Applications of MASS LOADED VINYL

They have variety of different applications

Open-plan

offices

Residential

Homes

car

soundproofing

Event

Venues

Construction

Sites

Manufacturing

Facilities

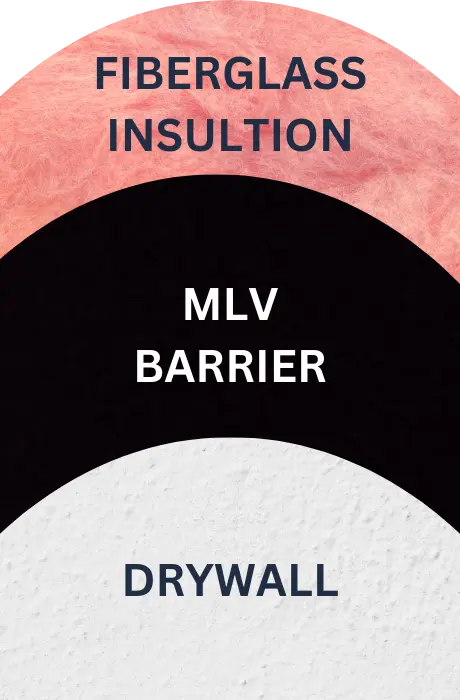

Components of an MLV Barrier:

An MLV Barrier is a multi-layered construction designed to maximize sound absorption and provide a durable, functional solution. Here’s a breakdown of its key components:

MLV Core:

The heart of the barrier, the MLV core is a dense, limp material responsible for the sound dampening properties. Typically, this core is made of polyvinyl chloride (PVC). The PVC is calendared, a process that heats and presses the material under high pressure, resulting in a uniform, high-density sheet. This density is crucial for effectively absorbing sound waves and preventing them from passing through the barrier.

Facing:

MLV on its own is a limp material and wouldn’t be very practical for installation. That’s where facings come in. These are the outer layers that sandwich the MLV core, providing several benefits. Facings shield the MLV core from physical damage, tears, and abrasions that could occur during installation, use, or maintenance. Sheet Metal a popular choice for its durability and soundproofing properties. It’s often used in industrial settings or constructions requiring a high level of sound isolation.

Reviews About Our MLV Barrier Service

Frequently Asked Questions

Absolutely! MLV’s dense composition makes it a powerful sound barrier. Imagine it as a shield that dampens sound waves, preventing them from traveling through walls, ceilings, or floors.

Sound travels in two ways: airborne and through structures. Airborne sound moves through the air, while structural sound vibrates through walls. MLV increases the density of a surface, making it harder for both types of sound to pass through. It also seals any gaps or cracks, further reducing sound transmission.

The effectiveness of MLV depends on its thickness. Thicker MLV has a higher Sound Transmission Class (STC) rating, which indicates how well a material blocks sound. Higher STC ratings mean better soundproofing.

For example, MLV with an STC rating of 27-32 can significantly reduce noise, making normal speech barely audible on the other side of a treated wall.

Absolutely! During new construction, MLV sheets can be placed between the studs for additional soundproofing. This creates a decoupled wall system that further enhances sound absorption.

MLV’s primary function is to block sound transmission by increasing mass. While it doesn’t absorb much sound like acoustic foam, it reflects sound waves back into the room. This reflection can create some echo within the treated space, but it effectively prevents sound from transmitting to adjacent areas.